The large European manufacturers of vacuum cleaners have worked out a standard describing how the various properties are to be defined and measured. IEC 312 / DS/EN 60312 Vacuum Cleaners for Use in the Household – Methods for Measuring the Utility Properties.

If you want to compare various vacuum cleaners you should make sure that they have been tested according to IEC 312. If the measurements have been made in accordance with this standard, it should be possible to compare the result with other results directly. Not all results indicated by the manufacturers are in accordance with IEC 312. Below please find examples of definition and the things to be aware of.

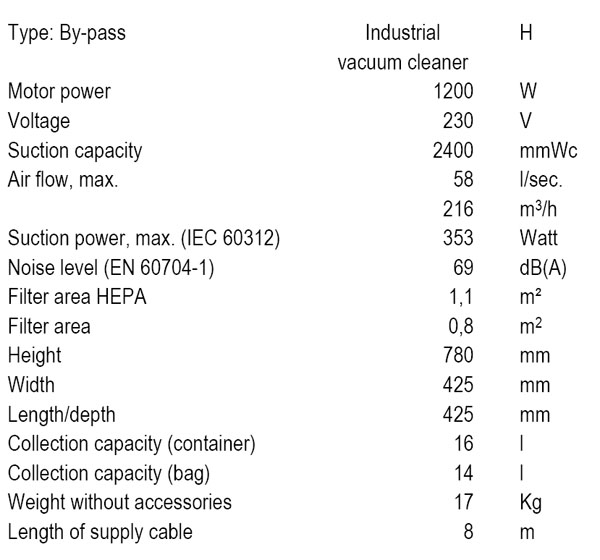

Technical data of the vacuum cleaner

The vacuum cleaner must always have a sign mentioning some of the technical specifications.

The technical data of an industrial vacuum cleaner may look like this:

The information of the sign may look like this:

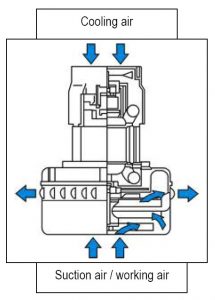

Bypass Motor

A bypass motor has its own cooling wing. It will suck the cooling air independent of the working air. The vacuuming air flows are blown out of the side of the turbine housing. In this way the motor is cooled, also even if the air flow is blocked.

This cooling method does not make the same demands on filtration of the working air, as this air will be blown out before it gets in contact with the motor. But demands are made on the filtration of the cooling air, if the room, in which the vacuum cleaner is used, contains many suspended particles.

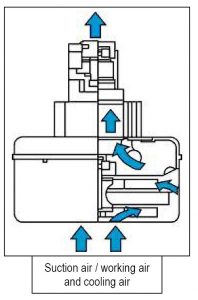

Blow through motor

A blow through motor is cooled by the same air that is used for vacuuming the material. This makes larger demands on the filters of the vacuum cleaner. If they are damaged or missing, the motor will be exposed to a large influence of dust and might consequently seize up.

According to EN60335-2-69 a blow through motor must not be used for vacuum cleaners intended to liquid, as liquid might be “pumped” through the electrical parts in case of an overfilled collection container.

Watt

The nominal and maximum motor power reflects how much energy the motor of the vacuum cleaner requires when functioning. The power is measured in Watt (W).

The typical consumption of Watt for industrial vacuum cleaners will be between 1000-4000 W depending on the application. For a machine with one motor it is typically 1000-1500 W. This size (W) is NOT an expression of how powerful the motor is or how well the motor vacuums, but only a measurement of how much energy the motor requires. (Compared to a car it is l / 100km). The suction capacity is more interesting than the electrical power of the motor.

Vacuum / Suction Capacity

Expresses how much negative pressure (lift) the vacuum cleaner is able to produce when the motor is running. The vacuum will be measured in mm water column or in Pascal (Pa). 10 Pa corresponds to1 mmwater column. The various household vacuum cleaners and industrial vacuum cleaners are able to produce from 2000 to3000 mmwater column.

Air Volume / Air Flow

It is not enough for the vacuum cleaner to loosen the dust; the dust must also be carried to the collection bag or the collection container. The capability to transport air containing dust is called air flow. The air flow is measured in l/sec. (litres per second) or m³ / hour. The level is between 25 and 65 l/sec. The larger air flow, the larger the capability is to carry the dust from the nozzle and into the bag.

For an H-marked machine – a vacuum cleaner for collection of dust hazardous to health – the air flow / air velocity in the suction hose must never be less than 20 m/sec. cf. DS/EN 60335-2-69.

Suction Power

The suction capacity indicates how powerful the vacuum cleaner is, and the air volume indicates how much air the vacuum cleaner is able to move. The suction power adds up the suction capacity and the air volume and indicates how much power the vacuum cleaner has. This is an indication of how good the vacuum cleaner is to clean – i.e. the work to be done. The suction power is measured in Watt (W) and is typically between 250 W and 450 W for machines with 1 motor.

The suction power is to be measured at the end of the tube of a complete vacuum cleaner (i.e. with tube, hose and filters – but without nozzle).

Some manufacturers show the results from measurements made at the suction of the actual vacuum cleaner. If you do that, you will obtain higher powers, which are not comparable.

A good cleaning result (dust collection capacity) will be obtained when the suction power is high and the nozzle of a good quality. I.e. the suction power together with the nozzle is to give a good cleaning result.

The result is shown as a percentage (%) and indicates the quantity of dust collected. The results obtained on hard surfaces are from 90 to 100% and on carpets from 50 to 85%.

Please verify whether the suction power is indicated according to EN60312, which makes is easier to compare the data of various vacuum cleaners.

Volume of the Bag

The measurement should be made with the bag in the vacuum cleaner, as it is often the room for the bag (in the vacuum cleaner) that decides the quantity of dust.

Some manufacturers measure the volume of the bag before it is placed in the vacuum cleaner. This makes the measure capacity too large.

Noise Level

The noise experienced can be measured in different ways. If you are5 maway from the vacuum cleaner, it is of course noisier than if you are20 maway. The acoustics and the reverberation times of the room have an effect too. If the reverberation times are too big there will be an echo effect between the walls of the room, and the noise will be measured and experienced considerably higher.

Noise is to be measured on the basis of DS/EN 60704-2.

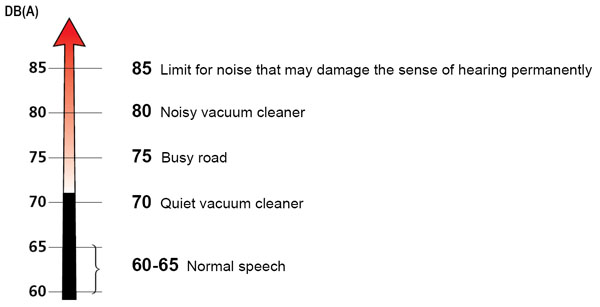

Decibel

The noise level from a vacuum cleaner is measured in dB(A). When measuring, the human ear is replaced by an electronic measuring device. Noise cannot be described objectively. A specific noise is perceived differently by different people/individuals. This is also due to the character of the noise. The noise may vary from 50 up to 85 dB(A). The diagram below shows noise facts generated by different sources of noise.

The statutory requirement according to the Directive on machinery 2006/ 42/EF is that machines are not allowed to have a noise level exceeding 80 dB(A).

For machines with a noise level below 70dB(A) you are permitted to write: <70dB(A). If the noise level is higher, you have to write the actual figure.

Dust classes and application categories

Application Categories

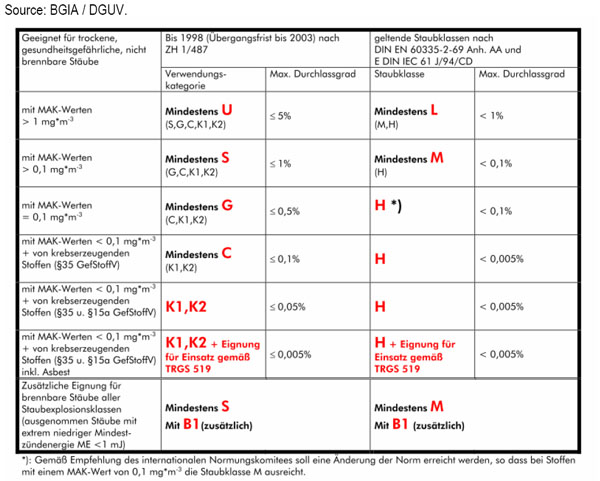

Industrial vacuum cleaners for dust hazardous to health are divided into classes depending upon their ability to retain the hazardous dust. Up to 1997 the vacuum cleaners were divided into the application categories U, S, G, C and K1.

Vacuum cleaners in for instance the application category C should retain 99.9% of the material collected. You were allowed to use a category C vacuum cleaner for collection of dust hazardous to health with a marginal value of more than 0.1 mg/m3.

The public health authorities have lists of hazardous substances and their marginal values.

Standards and Institutes

EN 60 335 -2-69

From 1997 new and stricter requirements for industrial vacuum cleaners for dust hazardous to health were introduced. The requirements can be read in the European standard EN 60 335-2-69. Inthis standard, the old application categories have been replaced by dust classes.

Dust Classes

Now there are three dust classes, L, M and H. The dust class H places the heaviest demands on the vacuum cleaner. The exhaust air must not contain more than 0.005% of the material collected, and the filters must not be loaded beyond a pre-set limit.

Filter Load

The filter load is determined by the quantity of air, which is drawn through the filter, and by the surface of the filter. The filter load must not exceed200 cubic metresof air per hour for each square metre of filter area.

Technical Institutes

Very few manufacturers of vacuum cleaners have testing equipment for approval of filters at their disposal. The majority of manufacturers use an authorized technical institute, when a filter is to be approved for a specific filter class.

DGUV / BIA / IFA

One of the internationally recognized institutes for approval of filters is the German Berufgenossenschaftliches Institut für Arbeitssicherheit, abbreviated BIA. BIA is an impartial institute testing the filter and guaranteeing that the filter satisfies the demands of the filter class in question.

SLG

SLG is a recognized German institute for testing of industrial vacuum cleaners for dust hazardous to health.

At the testing institute tests are made to prove that the vacuum cleaner lives up to the requirements concerning filtration among other things.

LGA

One of the internationally recognized technical institutes is the German Landesgewerbeanstalt Bayern, abbreviated LGA. LGA is an impartial institute that critically reviews whether the industrial vacuum cleaner lives up to the requirements of the standard. The external sign of fulfilment of the requirements of the standard is the GS-label. GS stands for Geprüfte Sicherheit (i.e. verified safety).

LGA was in 2010 merged with TÜV.

Technical Dust Test

Both BIA (IFA as from 2010) and SLG and also TÜV are able to carry out technical tests of industrial vacuum cleaners.

The technical dust test will test the filtration capacity of the whole machine – and not only the one of the filter.

If the vacuum cleaner is provided with good filters, but has many leaks, it can be observed and documented by this test.

GS-Label

Geprüfte Sicherheit (verified safety).

LGA allows you – after completed technical dust test and test with LGA – to use the GS-label in your marketing.

Approved Vacuum Cleaner or Approved Filter

There is a great difference between buying a vacuum cleaner with approved filters and buying an approved vacuum cleaner.

Class H vacuum cleaners must be equipped with approved filters and have passed through a dust technical test at an accredited test institute.

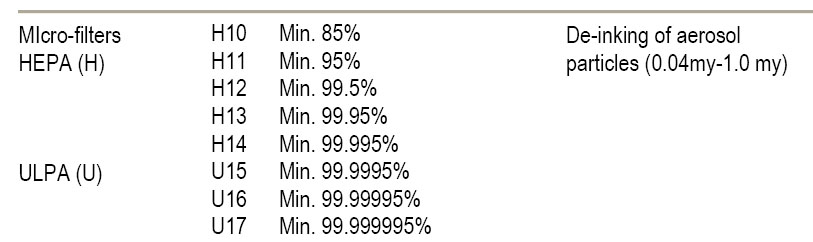

Class H vacuum cleaners are always equipped with HEPA filters. HEPA filters are available in HEPA 13 and HEPA 14. The figures 3 and 4 indicate the filtration degree (required).

H13 – minimum 99.95 % dust will be filtered (based on technical dust according to EN 60335-2-69)

H14 – minimum 99.995% dust will be filtered (based on technical dust according to EN 60335-2-69)

After H 14 the filters are called U15 and U16 (ULPA).

ULPA filters are mainly used as exhaust filters on clean room machines (CR).

Filters and Filtration

On its way back through the vacuum cleaner, the air is to pass one or more filters before it leaves the vacuum cleaner again.

Filter Bag

The first filter canbe a filterbag. The filter bag, whether it is made of filter paper or filter fabric, retains the large particles.

Pre-Filter

Filter No. 2 is a finer filter, which retains the fine particles. This filter is called the pre-filter of the vacuum cleaner. To a large extent it is the mode of operation of the pre-filter that decides how effective the vacuum cleaner is.

An effective pre-filter is self-cleaning during operation so that the filter does not clog up. The filter must have a large surface so that the intervals between the necessary filter cleaning are as long as possible. You canclean a high-qualitypre-filter from outside without having to take the vacuum cleaner apart.

HEPA-Filter

The third filter is often a so-called HEPA-filter. The letters HEPA stand for High Efficiency Particle filter. The HEPA-filter retains the very small particles, down to a size of0.003 mm. The particles of that size are so light that they float in the air. They are for instance found in tobacco smoke.

Filters with Certificate

If the manufacturer of the vacuum cleaner has decided to obtain an approval of his filter from a technical institute, a certificate will be issued. The certificate will guarantee to the customer that the filter fulfils the requirements in the filter class in question.

Filter Area

The area of the pre-filter of the vacuum cleaner is specified in cm2 or in m2. Generally, you may say that the larger filter area in proportion to the air volume, the better vacuum cleaner. The filter material and the filter structure are also of great importance.

It applies to H vacuum cleaners that the HEPA-filter must never be loaded more than200 m³ / h / m².

Furthermore it is required that the air velocity in the hose never falls below 20 m/sec. – and if the vacuum cleaner is used for extraction from tools and processes generating dust, it must be indicated when the velocity falls below 20 m/sec. This limit has been made to ensure the self-cleaning of the hose and the machine.

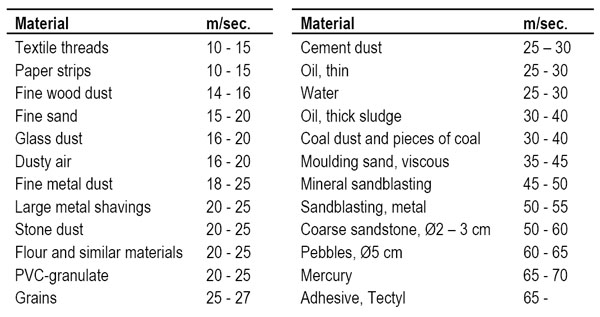

Suction capacity and air velocity

In order to be able to collect material through a suction hose or a pipeline, the air velocity must be adjusted to the material to be collected. The heavier the material to be collected is in proportion to the surface area, the higher air velocity in the suction hose and pipeline is needed.

The Air velocity is measuredin metres persecond (m/sec.). Below please find the air velocities recommended for collection of the different types of material.

The air velocity is dependent on the air volume that the vacuum cleaner is able to suck and on the diameter of the suction hose.

The greater air volume, which the vacuum cleaner is able suck, the greater the air velocity becomes.

As to the diameter of the suction hose it is the opposite: The thinner hose, the higher air velocity

A Practical Example:

A vacuum cleaner is able to suck an effective air volume of 150 m3/h through an Ø40 mm suction hose. The air velocity in the suction hose can be calculated to 33 m/sec.

From the above diagram you can see that the vacuum cleaner is able to collect for instance grains and cement dust.

If you now mount an Ø50 mm suction hose on the vacuum cleaner, the air velocity in the hose will fall to 21 m/sec. With this thicker hose the collection of grains and cement dust will be difficult, whereas textile threads and strips of paper are collected without problems.

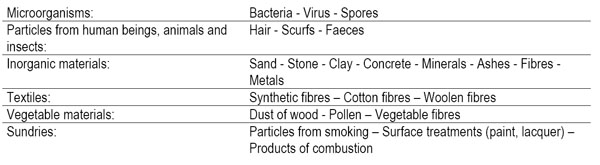

What is dust?

Dust is also often called particles. There are naturally existing particles, and there is the man-made emission of particles, also called anthropogenic emission of particles.

A particle is a small limited mass of solid or liquid substance.

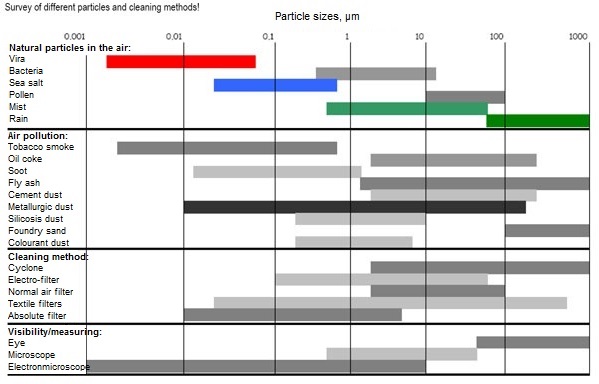

The size of the particle is, as the name directly indicates, a specification of the actual size of the particle (diameter) and is typically indicated in the unit [μm]. 1 μm is0.001 mm.

The man-made emission will most often occur in connection with energy producing systems, traffic and many industrial activities, such as production of grain and feeding stuff, production of cement, wood processing companies etc.

Depending on the activities of the individual company or the individual system, emission of particles with different sizes can occur.

The Consequence of Dust

There is always dust in the indoor air, and consequently also in the air we breathe in. The dust can cause irritation of mucous membranes and respiratory passages. Several circumstances determine whether dust feels irritating or is a risk to the health. The quantity and the composition of the dust, and also the shape and the size of the individual particles are important. But also the ability of the dust to absorb or catch gaseous air pollution is of importance.

When the dust lands on a moist mucous membrane, for instance in the nose, acid or base may be formed and cause irritation. The risk of inconveniences is also very much connected with the efficiency of the system of each individual person to remove the dust particles from for instance the respiratory passages and the mucous membrane of the eyes.

When you breathe, the dust in the air will follow the breathing air down into the respiratory passages. How far the dust particles come depends on their size. While the smallest particles can reach the lungs, the larger ones will normally stick in the nose and the throat.

Of what does Dust consist?

House dust often consists of several hundred different ingredients – and, some times, also allergens. Inorganic particles in the dust can give inflammation, but they can also act as carriers of allergens.

The word dust is normally combined with the visible dust you see on horizontal surfaces such as table tops and shelves.

These are the large particles from the indoor air, which have been deposited on the various surfaces. In addition to that there are a number of very small dust particles floating around in the air.

Normally 99% of the total number of dust particles of the indoor air is made up of particles smaller than 1 μm, while the large particles are the main part of the total weight. The smaller the particles are, the longer time they will keep floating in the air.

The number of particles in the air also depends on the activity in the room. In rooms with ventilation, or when persons in the room move about, particles of a few μm keep floating in the air.

Definitions of Dust

Coarse Particles

Particles larger than 2.5 μm are typically produced by different mechanical processes. Coarse particles can consist of different substances depending on their origin. As an example of emission of large particles we can mention emission from the concrete products industry, feeding stuff manufacturing companies and various surface treatment processes, including sandblasting. Fly ash from heating with solid fuel and from waste burning and also coal dust from coal-burning power stations are examples of large particles too, just like oil coke from fuel oil-burning systems.

Fine Particles

These particles are a result of a number of conversion processes, among other things in connection with chemical processes between particles and gasses. The fine particles mostly consist of hygroscopic (hygroscopic is the name for substances which will easily absorb aqueous vapour from the surroundings), inorganic salts, e.g. sulphates, nitrates or chlorides. The most considerable sources of fine particles are burning of sulphurous fuel and also all burning processes, which give rise to the formation of nitrogen oxides, including among other things traffic, power stations, heating etc. Emission from among other things metal processing companies, including welding smoke, can similarly bring emission of fine particles; and also wood dust from manufacturing processes is an example of emission of fine particles.

Fine particles are defined as particles larger than 0.1 μm and smaller than 2.5 μm.

Ultra-Fine Particles

Ultra-fine particles are made from vapour state at high temperature, for instance in internal combustion engines and in case of condensation, and grow quickly from a few molecules to ultra-fine particles, typically of the order of 0.001 – 0.1 μm, when the temperature falls at transport through exhaust pipe or flue. The ultra-fine particles mostly consist of organic, hydrophobic substances, e.g. carbon, oil drops, complex organic compounds (PAH) or oxidized organic substances. The most considerable source of emission of ultra-fine particles is the traffic, including especially diesel engines. Emissions from various production processes can also contribute to emission of ultra-fine particles, including for instance the production of asphalt and also the pharmaceutical industry.

Dust and Fibres

Dust in the indoor climate consists of organic and inorganic particles and fibres coming from outside, from persons, animals, clothing, paper, building materials, mould fungus etc.

Therefore the contents of dust in rooms depend on the materials existing or being brought into the rooms, and from the activities going on, but also on the fact whether the dust will be removed by cleaning or ventilation. The dust is found in the air or on surfaces, for instance flooring, which particularly can be dust depots.

The concentration and composition of the dust being inhaled or deposited in the eyes or on the skin are different from the ones in the air or on surfaces. The dust being measured most often is therefore only to be considered as an indicator of the influences.

The limiting values of the different kinds of dust in the air are all normally much higher than the concentrations in the indoor climate.

Airborn Dust

During normal activity the content of dust in the air vary from 0.05 mg/m3 to 1 mg/m3. The high concentrations are normally brief because of brisk activity or smoking. In dirty indoor climates with high activity, such as schools, average values of 0.5 mg/m3 have been measured during several hours.

The average concentration of airborne dust can in clean surroundings without much activity be under 0.1 mg/m3. It ought to be under 0.15 mg/m3 in offices. In schools and day-care centres it is often larger than 0.2 mg/m3.

The limiting values for places of work are from 3 mg/m3 for organic dust to 5 mg/m3 for inorganic dust.

The part of the dust breathed in and reaching the lungs is usually much smaller than the total quantity of dust.

Deposited Dust

An indicator of the dust load or the cleaning is dust deposited on floors and other surfaces.

If you are able to collect more than 0.5 gdust / m2 floor with an ordinary vacuum cleaner, after having cleaned, the cleaning is not sufficient.

You can express a dust concentration in per cent dust covered area. Less than 1 per cent dust on for instance table surfaces reflects a clean surface. More than 5 per cent is considered to be unacceptable high in an office environment, but no connection has been found between these figures and inconveniences or symptoms.

Mineral Wool Fibres

Mineral wool fibres are found in almost all buildings, but it is only critical where not enclosed mineral wool has been present or is present.

Recommended values for acceptable concentrations are 1000 fibres per m3 air and 30 fibres per cm2 on cupboards and tables, but often there is only one third of these values.

The Rest of the Ingredients of the Dust

The dust contains bacteria, virus, spores and other allergens, and organic gasses and vapours may be on the dust. It might be relevant to measure the existence of allergens, but the best way to do this is to analyze dust collected from the floors or other places.

Survey of Different Particles and Cleaning Methods

The filtering degree for different type of fine filters

Filtration

Besides collecting dust or liquid the purpose of the vacuum cleaner is to hold back the dust so that it will not be blown back into the room. Besides the bag the vacuum cleaner is equipped with one or more filters.

The purpose of the pre-filter is – besides holding back the particles that may escape from the bag – to act as a safety filter, if the bag for some reason should break. In this way the motor is protected.

Before the air is blown out into the room again or after the pre-filter you have a last possibility to clean the air by means of an exhaust filter or a motor filter. These filters can have different names and efficiencies. Micro filter, electrostatic micro filter or HEPA-filter.

High Efficiency Particulate Arresting (HEPA) filter came into existence many years ago. In the nineteen fifties theUSnuclear research should use a filter to remove small radioactive particles. Since then the HEPA- filter has been used for many things. HEPA-products are also recommended by the “Asthma and Allergy Association” for vacuum cleaning.

BUT what is a HEPA-filter, and when is it a HEPA-filter?

The Danish Working Environment Service describes a HEPA-filter as follows:

Absolute filtration will typically be in the form of a HEPA-filter, which holds back particles down to approx. 0.1μm. The filter will not hold back gasses and other pollution. The filters are divided up into classes by the percentage of small particles held back, for instance H13 has an efficiency of 99.95% and H14 an efficiency of 99.995% (the figure after H1 states the number of nines).

A HEPA-filter is to remove at least 99.97% of all airborne particles larger than 0.3 µm which is 1/300 of the diameter of a human hair.

A HEPA filter is according to the DS/EN60335 standard to be mechanically protected and therefore mounted in a casing with grating or the like.

The de-inking degree shows how efficient the filter is to hold back fine particles (0.4 my – 1.0 my).

Filter Efficiency

A filter will typically change filtration capacity as the filter is loaded with dust. The filtration capacity will always grow to begin with and will usually gradually fall. Therefore it will often be necessary to take the filtration capacity TO BEGIN WITH and DURING THE PERIOD into consideration. The filter classes are only based on the AVERAGE filtration capacity.

At the same time the pressure drop above the filter will rise as the filter is filled with dust. Please note that there are different development curves for the rise in the loss of pressure depending on the filter material used.

Filter Classes

The filter classes are defined in standard DS/EN60335-2-69 Annex AA.

This standard deals with: Vacuum cleaners for industrial use – Annex AA dust hazardous to health.

IT is important that the vacuum cleaner has been classified and not the filter only. (Vacuum cleaner with approved filter).

MAK values can be found in the AT Guide C.0.1 Marginal values for substances